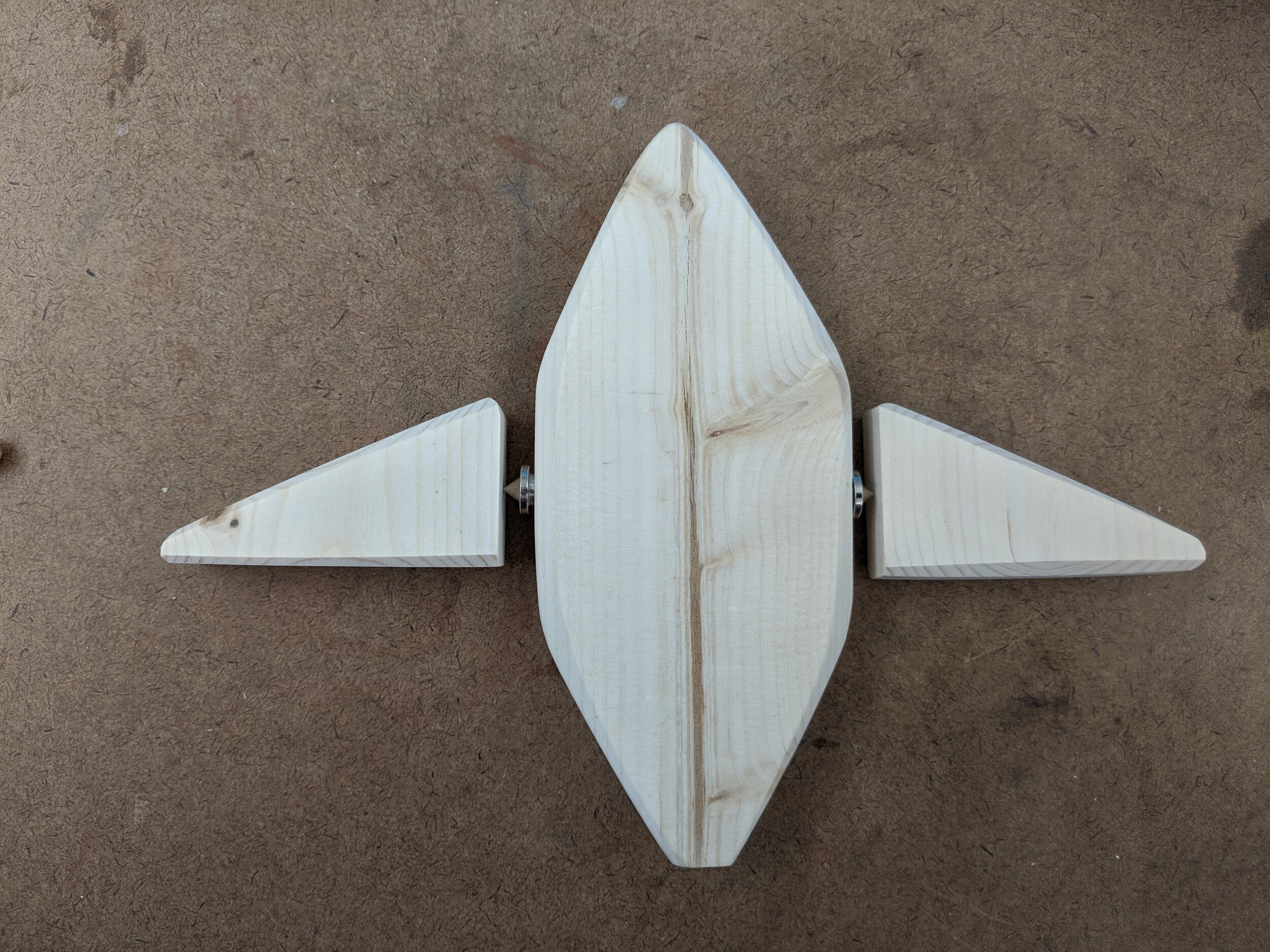

Our assignment was to make five of something. The point of the assignment was to get a feel for developing a production process. The process for making one of something is very different than the process for making an assembly line of somethings. It was pretty easy coming up with an idea on what to make, because my wife and I are expecting a baby boy at the end of February, and obviously I should make some wooden toys for him. So, wooden spaceships (that’ll float nicely in the bathtub).

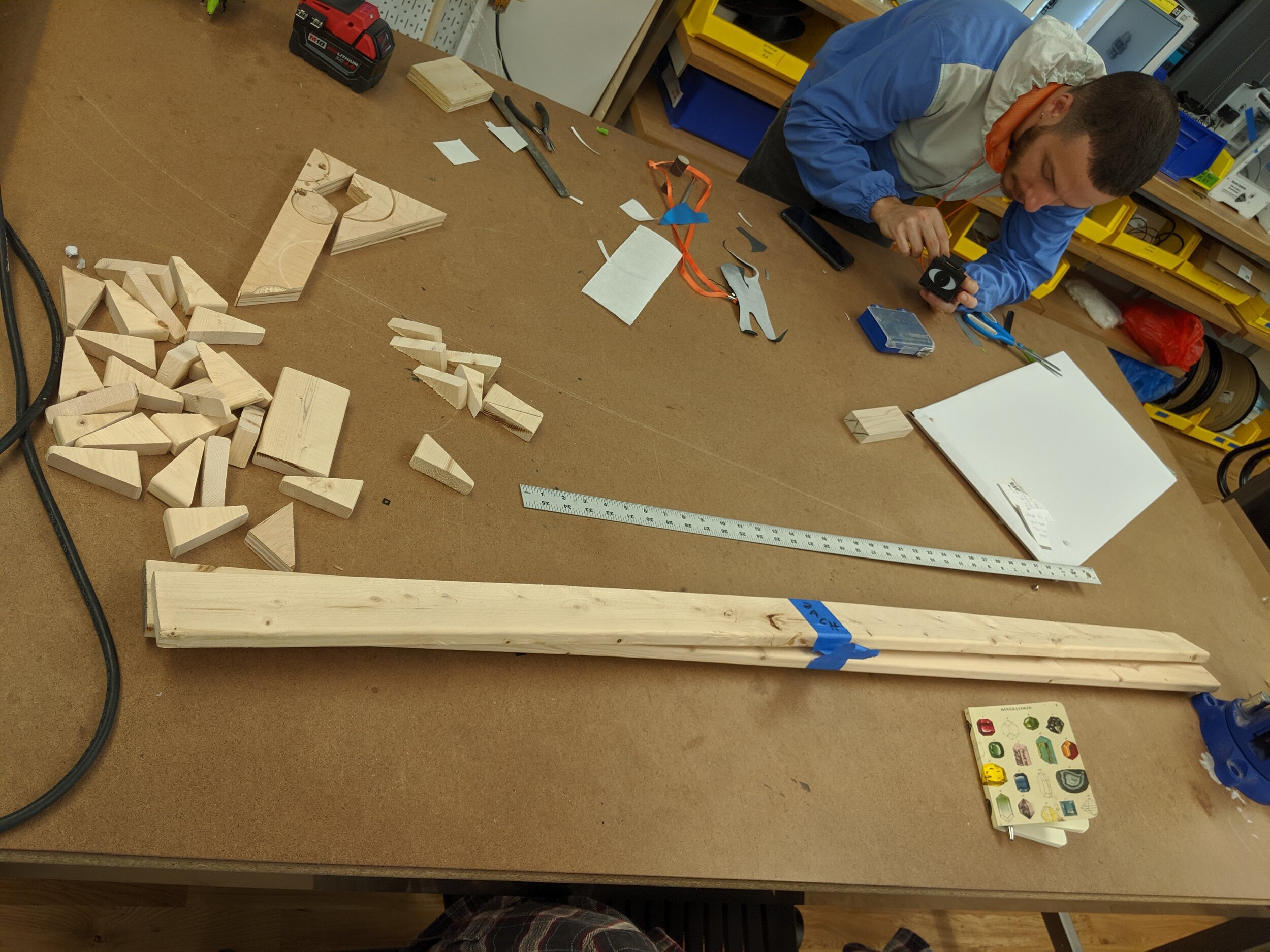

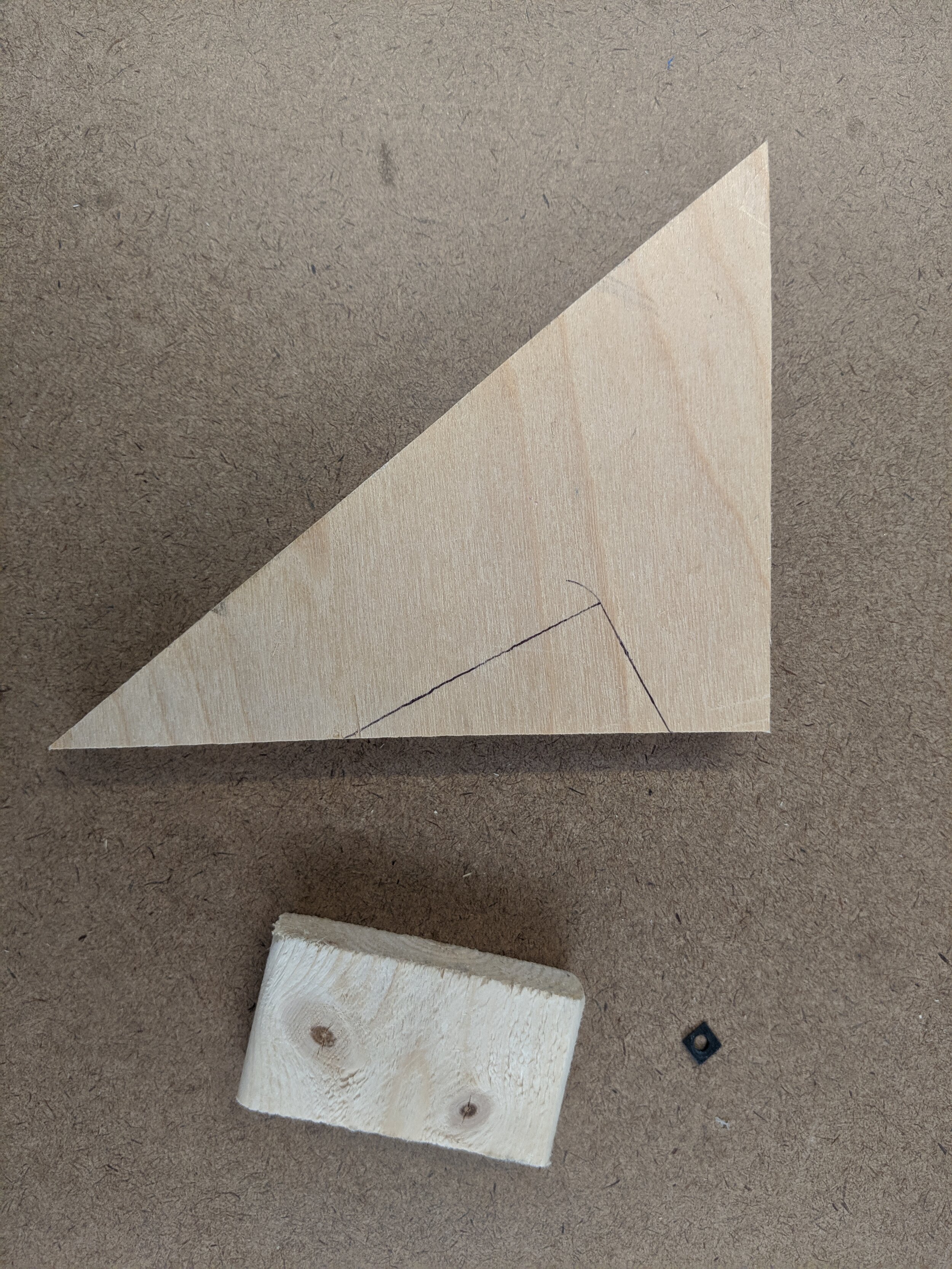

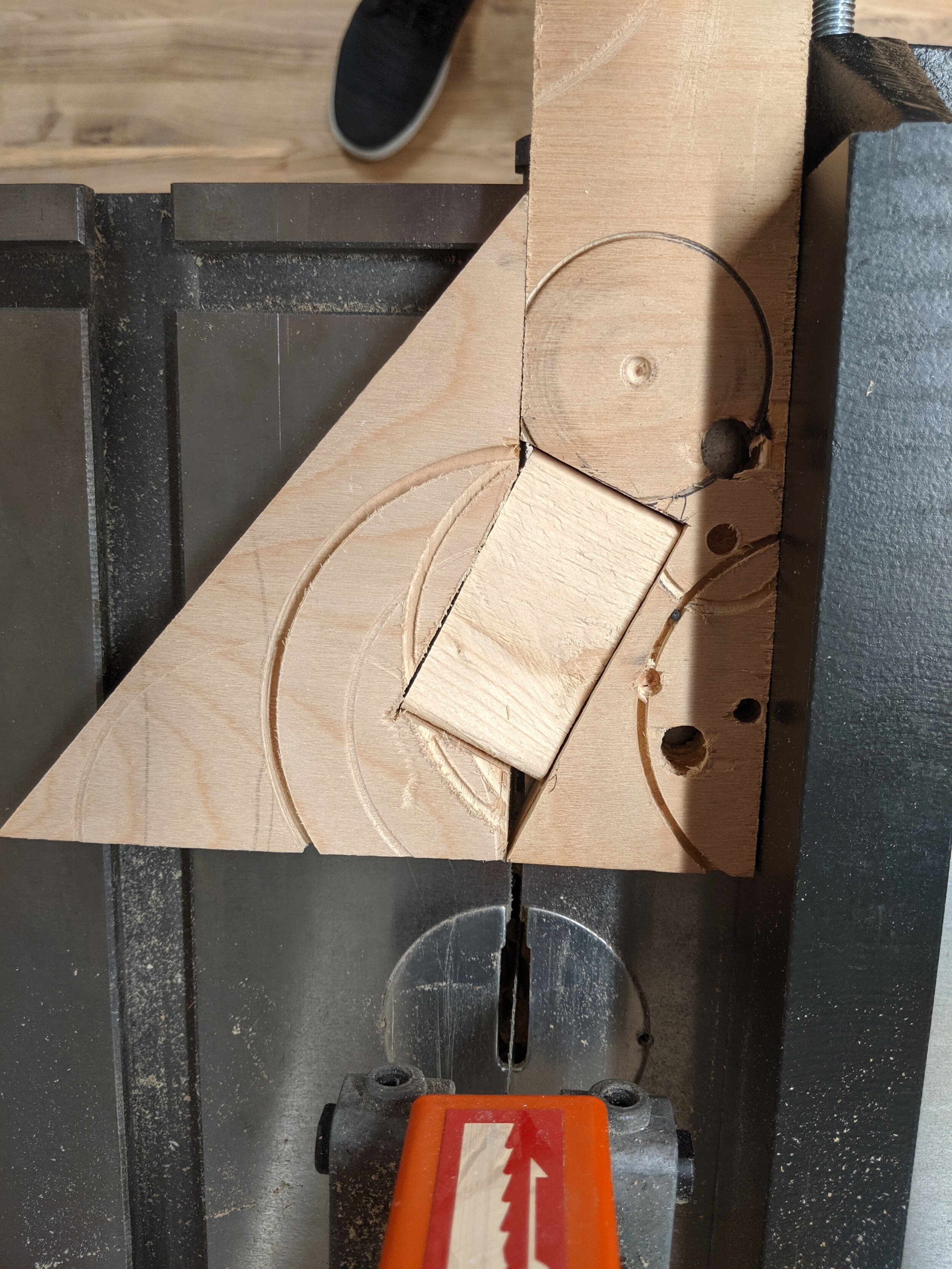

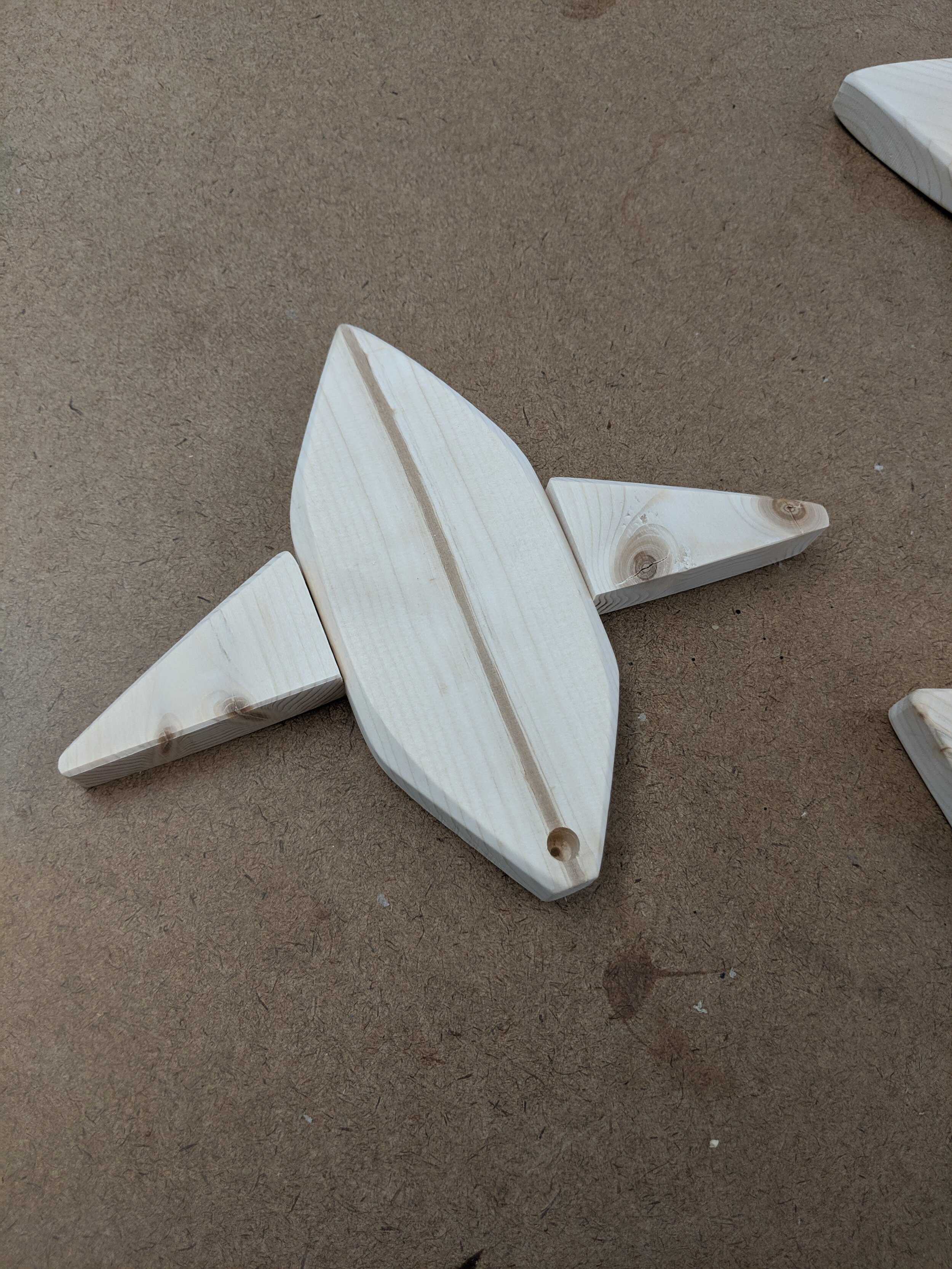

I had some wood planks from an old project hanging out in my closet at home, so I decided to use that for my material. I started by creating a jig for cutting my wings. The pieces are too small for the miter saw or the band saw, especially when cutting at an angle (lest I lose my fingers), so I made my first jig. Its sole purpose is for making wings for my wooden spaceships. The next slideshow shows my materials and custom jig.

Then I cut all of the lengths of wood for the body of the spacecrafts, made the angle cuts for the basic shape on the band saw (oh, all the cuts were on the band saw by the way… the miter saw in the shop was down for the night), and sanded everything nicely on the belt sander.

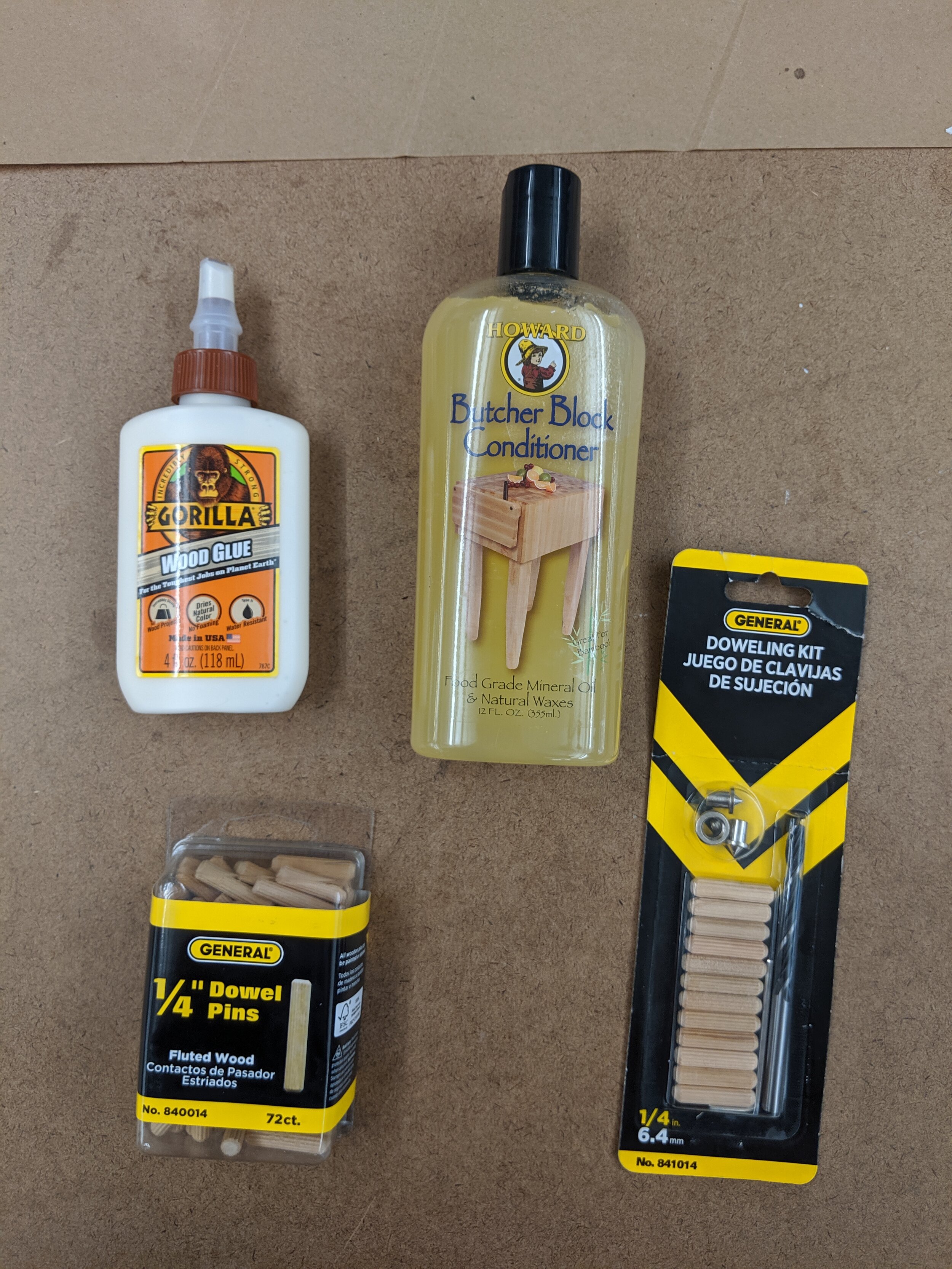

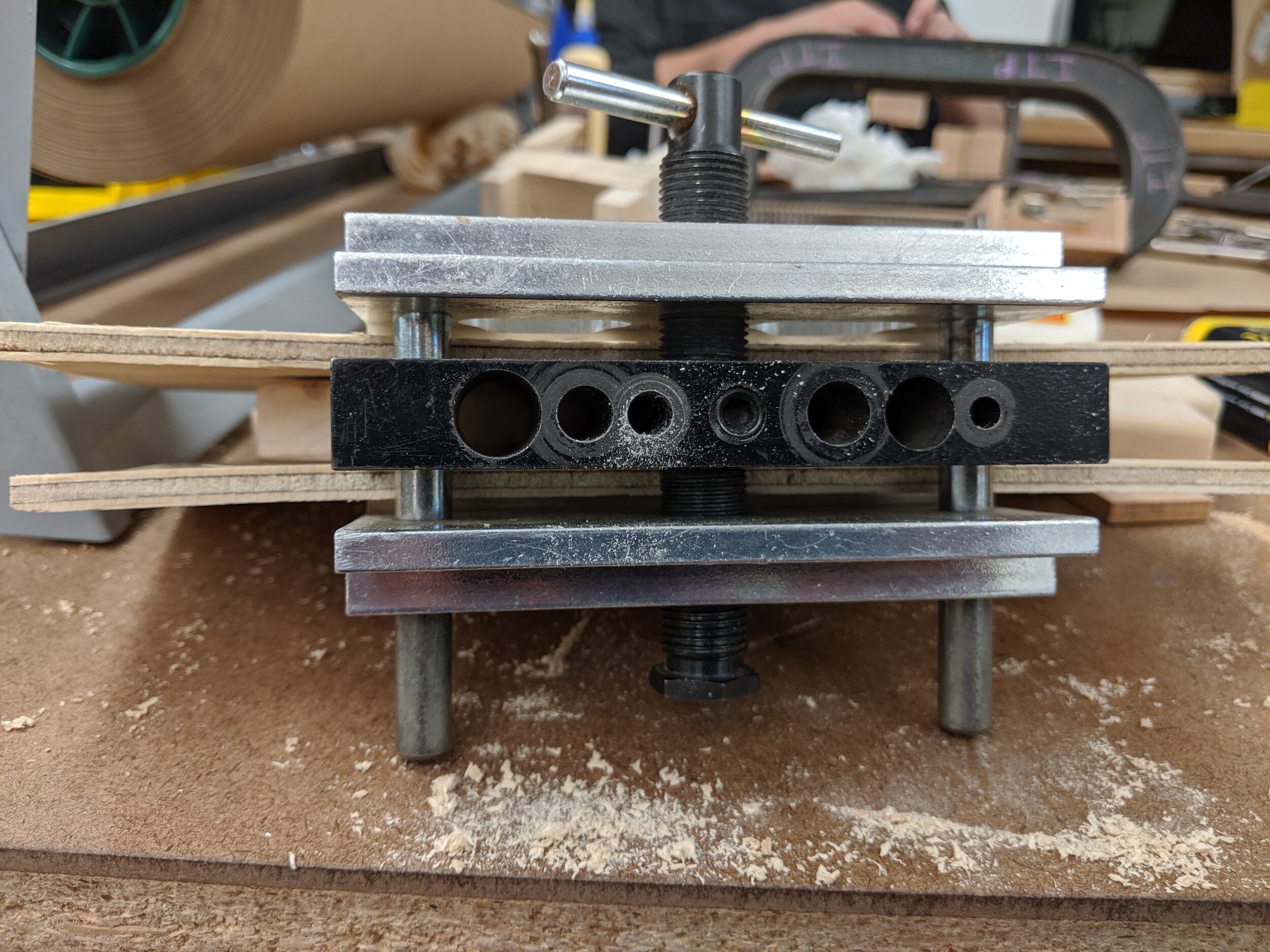

That was it for the first evening of my spaceship production. The next even I did all of my doweling. I picked up a doweling pin kit from home depot, brought it to ITP and set up shop with Ben Light’s doweling jig. I used 1/4” doweling pins to fasten all of the parts together. Then I put a little bit of wood glue in the holes and on the contact edges, and clamped them to dry.

The doweling kit was cool. It came with these little metal pins that you put inside your dowel holes to mark out where they’ll connect to their corresponding part. Pretty nifty. After doweling and gluing, I sanded everything one more time by hand with a fine grit sanding block (not sure of the grain, I borrowed it from Mark). Then I treated everything with butcher’s block conditioner. I wanted to use a sealant that would be safe for my son. I didn’t want to use lacquer or varnish. I did a little research and landed on butcher block conditioner, which is just a mixture of mineral oil and beeswax. I tasted it. Not bad.

It recommended four coats, so that’s exactly what I did. But first it recommended warming it up, so I put it in a plastic pitcher from the ITP kitchen with hot water.

Butcher Block Conditioner warming up in hot water.

Wooden spaceships sealed up and drying.

And there you have it. That’s how you build wooden spaceships. The jig was the most significant part of my batch process. Making all of the wings one at a time would have been significantly more tedious and inconsistent without it.